How Cold Welding can Save You Time, Stress, and Money.

Wiki Article

Getting The Welding Table To Work

Table of ContentsLittle Known Questions About Smaw.The 9-Second Trick For Underwater WeldingExcitement About Arc WelderFascination About Welders Near MeWhat Does Welders Near Me Mean?Not known Facts About Underwater Welding

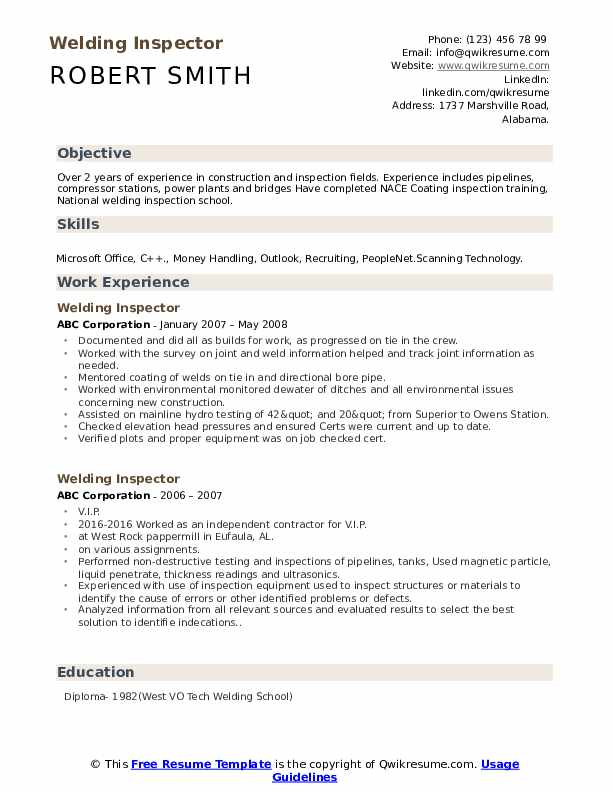

Expertise of just how to gauge the different weld top quality demands using specialized weld evaluates and so forth. Basic knowledge of Non Destructive Screening (NDT) needs and abilities. While the knowledge base is essential to receive welding inspector jobs, simply as crucial is having the ideal personality for the work.The pressure positioned on welding assessors by manufacturing workers when a Does Not Comply (DNC) call is made can be really substantial. If you experience anxiety when having to taking on strong willed people, this might not be the work for you. If this does not phase you, after that this element of the welding examiner work must not create you unnecessary stress and anxiety.

A case in point being CSWIP in the UK. An additional organization that is taking a leading role internationally in the accreditation of personnel for welding examiner work is the International Institute of Welding. (IIW) The International Institute of Welding is really quite an old company, yet its influence on the certification side of things is in fact only quite current.

Things about Spot Welder

Please keep in mind that it is not possible to come to be a professional in all welding codes. There are way a lot of. If you are presently a Welder and also you want to start acquiring direct exposure to welding codes so that you can prepare yourself for a life as a welding inspector, after that I suggest you concentrate on the following codes: ASME IX: This is geared to the welding of pressurized tools such as piping and also pressure vessels.

API 1104: This is tailored in the direction of pipe welding. Usage relatively extensively, although pipeline codes do often tend to have an extra local prejudice. Several of the more neighborhood pipe welding codes are loosely based on API 1104, so a good basis to have.

3 Simple Techniques For Welding Shops Near Me

It is utilized internationally, but the main usage remains in Europe. While the codes over are great beginning factors, there are many various codes, criteria as well as specs that the welding examiner will aluminium welding near me certainly need to obtain an understanding of. These criteria handle topics as diverse as welding plasma welding consumables, base products, devastating and also non-destructive testing techniques, quality administration systems and so forth - mig welder.You get to know the base codes, and afterwards you practically be familiar with the others via "at work" training for many years. The particular criteria and codes being dependent on your specific market. The larger exposure you reach codes and requirements, the much better a welding assessor you will be.

Top Quality Systems Expertise Central to the job of the welding inspector is the quality control and also control function - welding table. This is not only based on technological welding knowledge, however also quality systems expertise. Within this component of your job you will get to deal a great deal with high quality management system requirements such as the ISO 9000 collection of standards, and additionally the ISO 3834 series of requirements.

Everything about Arc Welder

Quality Control (QA) and Quality Assurance (QC) are greatly driven by recorded systems and also rely upon files and records to have traceability and an auditable system. All of this will be central to your work as welding assessor. If you are overly discouraged by paperwork, after that you might not appreciate the life of a welding inspector.The Welder, Destiny Compass: Weekly e-zine Membership.

Assessors measure bonded items to make sure that they meet requirements for measurement. The licensed weld examiner makes use of tension equipment to place anxiety on weld joints.

Everything about Arc Welder

Inspectors likewise check weld maker arrangement and the welding techniques of welders on operate article in progress to ensure the high quality of the job. Welding inspectors tape the results of tests as well as welding evaluations. Certifications, Employers might need a secondary school education and learning for a certified welder placement. An university education and learning is not required for many welding or welding examination positions, but an associate degree in welding modern technology can boost the possibilities of landing a task.

Something failed. Wait a minute and attempt again Try once more.

The Best Guide To Spot Welder

Senior Personnel Engineer, National Board This write-up was initially released in the Autumn 2009 National Board notice as the initial of a two-part series. Please see Fundamental Weld Evaluation - Part 2 for the conclusion of this article. Keep in mind: The objective of this short article is to supply examiners with a basic expertise of weld inspection.

While not crucial, the examiner must find out to check out typical weld signs such as the AWS signs. welders near me. At least, the assessor needs to always bring a recommendation guide to analyze weld symbols. Having reviewed all this information ahead of time, the assessor will certainly be prepared to acknowledge any kind of troubles as they establish as opposed to after-the-fact.

The supplier or repair work company (certificate holder) has suggested on the job attracting that a weld joint is to be prepared with a 60-degree bevel as well as origin space of 1/16 inch. Unless the bevels are milled on accuracy machinery, it is uncertain they will attain a specific 60-degree bevel as suggested.

Report this wiki page